What is Hydrotesting ?

Science and technology ventures limited has set up the first periodical CNG Cylinder testing unit in Rajasthan India approved by PESO,GOVT OF INDIA. Our Testing Facility equipped with the latest, world class high tech instruments. Use of CNG as fuel is safe and environment friendly. Many safety rules and standers have to be followed during manufacturing and using the on board cylinder. Retesting is the part of this standard norms & procedure to be followed by user of cylinder while using CNG as a fuel in their vehicles. For the safety of owner, people as well as public property, Filling station fills only retested cylinders as per the guidelines of petroleum & explosives safety organisation of india.

Apart from CNG Conversion, M/s Science and Technology Ventures Limited has set up the first periodical CNG Cylinder testing unit in Rajasthan equipped with the latest ,world class high tech instruments. What is Hydrostatic Testing and why is it important? Hydrostatic Testing is a nondestructive test procedure used to check cylinders for leaks, structural flaws, durability, and corrosion. It is used to check a cylinder’s structural integrity. Testing consists of enclosing a cylinder filled with water inside a test jacket filled with water. Pressure is then applied internally to the cylinder, causing the cylinder to expand. The total and permanent volumetric expansions of the cylinder are determined by measuring the amount of water displaced by the expansion of the cylinder when under pressure and after the pressure has been released. An external and internal visual inspection of the cylinder is also performed.

CNG Cylinder Testing CNG cylinders are required to be tested periodically every 3 years. Following are the aspects of cylinder testing :

What is The Process Behind Hydrotesting ?

- 1. De - Pressuring & Degassing of Cylinders.

- 2. Valve Opening.

- 3. Internal and External cleaning of Cylinders.

- 4. Internal Inspections.

- 5. External Inspection (thickness , bulge , burn , denis ,dig)

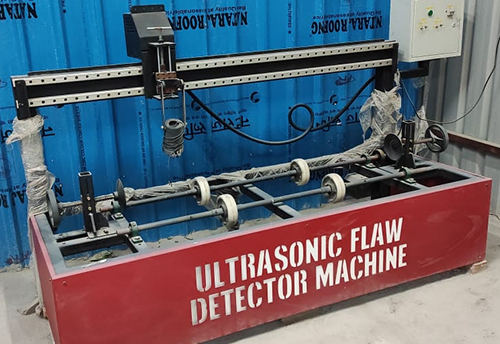

- 6. Cylinder wall Thickness measurement by Ultrasonic Thickness Tester .

- 7. Hydrostatic Test by Water Jackt method.

- 8. Cylinder Drying & Painting.

- 9. Fixing of Valves.

- 10. Nitrogen Purging

- 11. Test mark sign is used after testing fitness of the Cylinder.

- 12. Assemble & Diassemble of CNG Cascades Delvier the cylinder with Certificate.

All Rights Reserved By Pune CNG